-

Posts

3887 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Everything posted by Enthalpy

-

In the closed loop, you have more elements than the circuit portion where the EMF is induced. For instance the voltmeter that measures the induced voltage. It could be resistors that drop this voltage, batteries, capacitors, coils that store the produced electrical energy...

-

Why is the nitrogen-nitrogen bond so strong?

Enthalpy replied to Ordinis's topic in Applied Chemistry

The nitrogen molecule has a perfect configuration of molecular orbitals for all its electrons. That makes the molecule very stable, unreactive, good insulator and so on. Each nitrogen atom has three 2p electrons, making six for the pair of atoms. Atoms have three 2p orbitals; two atoms close to an other make six molecular orbitals resulting from atomic 2p: - Three such orbitals are bonding, with favourable energy; - The three others are antibonding (they're better for an electron than far from the nucleus, but less so than at the 2p of a lone atom). - Each orbital can accept two electrons of opposite spin, so the bonding molecular orbitals take six electrons: perfect. If you compare with the oxygen molecule: it has 2*4 electrons to put on the molecular orbitals resulting from 2p, but only six places are on bonding orbitals, so two electrons must go to antibonding ones. These electrons are less bonded to the molecule and ready to react. You can search for "singlet oxygen" for more funny observations and explanations. -

Where did you get that "space is cold"? This has mislead you. An atmosphere, preferably windy, equalizes object temperatures as it transports heat well, so one can define a common temperature. Vacuum lacks such a common temperature - which does not imply that space is cold! Objects get warmed by Sunlight and they cool by radiating infrared. At Earth's distance to the Sun, half-efficient absorption and emission result in habitable temperature, for Earth as for any object. Greenhouse effect adds a bit to it but is secondary. The main difficulty with temperatures in space is that they vary brutally because no atmosphere regulates them. Sides exposed to Sunlight get hot, sides in the shadow cold - too brutally for humans, batteries, most sensors, many plastics, long-lasting electronics... So obtaining regular bearable temperatures is a difficult challenge in spacecraft design.

-

What is this moving light in the sky?

Enthalpy replied to Jerry Wickey's topic in Astronomy and Cosmology

Not moving at 15' per minute as the stars do, and not over the Equator: - Solar sails have been proposed for that purpose, especially to stay over a fixed location at high latitude, say for radio transmissions over the Arctic. To my knowledge, none has been tried with this aim. - A strong ion thruster like Vasimr (none is operational to my knowledge) could keep a satellite stationary slightly outside the Equator for a limited time with unreasonable Solar arrays. My Solar thermal engine could keep it 10° outside the Equator for two months. But for what purpose? - An aerostat? Weather balloons are common, but they seldom carry a light, and they use to climb then fall. Bigger ones would. - A drone, especially a quadrotor. So many people operate one presently! Most do it a very low altitude, but technology can let them fly high. Observation, data comms... Some are planned (or already used?) at the Mexican border - officially voted by your Parliament, nothing of a conspiracy theory; a higher altitude looks better. In Florida it could be the Coast guards. - A laser shot to the sky. Astronomers do it for adaptive optics, but they don't choose Florida. Meteorologists use some to sound the atmosphere. -

http://www.scienceforums.net/topic/70114-aerostat-buoyancy-control/ http://saposjoint.net/Forum/viewtopic.php?f=66&t=1684 (drawings begin on Fri Jul 10, 2009 2:43 pm) http://www.scienceforums.net/topic/69058-antireflective-package-for-optoelectronics/ http://www.scienceforums.net/topic/74606-blinds-stick-with-laser-tactile/ (try to buy the range laser) http://www.physicsforums.com/showthread.php?p=4123014#post4123014 http://www.chemicalforums.com/index.php?topic=68477 (simple if not automated) http://www.chemicalforums.com/index.php?topic=57335.0 http://saposjoint.net/Forum/viewtopic.php?f=66&t=1974 (just demonstrate the low-loss bearings) http://www.scienceforums.net/topic/72310-pour-your-brains-here-on-how-to-build-this-contraption/ http://www.chemicalforums.com/index.php?topic=46384.0 http://www.scienceforums.net/topic/70340-reactor-for-liquid-and-gas/ http://www.scienceforums.net/topic/78265-solar-sails-bits-and-pieces/ (I'll put some mast designs; demonstrating one section is enough) http://www.saposjoint.net/Forum/viewtopic.php?f=66&t=2520 http://www.scienceforums.net/topic/69094-what-polymer-did-i-obtain/ http://www.scienceforums.net/topic/78116-airlock-with-saving-tanks/ a car or boat that sails against the wind directly (a wind turbine powers wheels or a propeller) What do you call "technology"? There would be more ideas for pure chemistry or software.

-

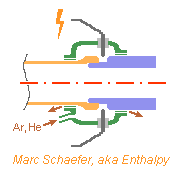

Hydraulic actuators fit well Linear Friction Welding after all (changed my mind) and can exceed 100Hz if needed, especially if they use rotating distribution valves aided by proportional valves in series to regulate the amplitude and the mean position. But a serious difficulty here is that tubes risk to collapse instead of transmitting the shear force to the weld location. So here's a welding appartus by melting; it's semi-automatic because there are 1800 tube ends. It's a MIG process. Two or few shell elements are fit manually around the tubes to guide the flow of inert gas and hold the electrodes in place; the rest is automatic. The fittings around the tubes can have for instance shallow grooves as gas outlets. Instead of moving a unique electrode, I imagine many (like 60) static electrodes are easier in the limited room. Each has its electric supply, and probably its mechanical feed. I expect all electrodes active at the same time would let the molten metal flow too much under gravity, but several can operate simultaneously to get a more symmetric seam. Standard pratices, like a few points before the continuous seam, are possible. Some tungsten electrodes can start the seam if better so. Instead of mechanically feeding the welding wires, maybe the material can be stored and brought liquid through hollow tungsten electrodes, which is more flexible since melting the base material is decoupled from supplying the feed, but this relies on tungsten not melting - it's cooled by liquid aluminium , but unfortunately not when starting the seam. This would apply to any MIG process; it's a confluence with TIG. The feed alloy must not segregate when liquid for long. Marc Schaefer, aka Enthalpy

-

Asking for ideas in Internet forums is meanwhile common practice in the industry and research, so I see no reason why students wouldn't learn that too . At least raiool's quest is not disguised and is for good purposes. One option is to alternate cones and cylinders as the tower gets broader at the base, because angle stiffen the shell, which is important against buckling. Some power pylons were built that way. This may suffice even at the base, since 3 paper sheets are light. Alternate often enough there. If a single cone-and-cylinder doesn't suffice, you'll have to resort to a truss, which requires more work.

-

What is this moving light in the sky?

Enthalpy replied to Jerry Wickey's topic in Astronomy and Cosmology

Big satellites on low Earth orbits are easily seen with the naked eye; a sextant has a light collecting area similar to an eye, doesn't it? As they fly in Sunlight while the observer on Earth is in the darkness, which can be over 2 hours from dusk and down in Summer depending on the latitude, they can be very visible. The huge ISS can be much brighter than Venus and Jupiter, catching one's attention without prior notice; the fainter I saw was a Progress vessel (already several m2 with the Solar panels) which was very faint. Passing at 200-800km altitude, they show an apparent speed similar to airliners, without blinking colour lights but they can tumble, especially so launcher upper stages. Their angular speed is constant for the eye. They can disappear in the clean sky when entering Earth's shadow; as one can see 3-5 of them within an hour of good conditions, they all disappear in the same region. The path is variable; at 300km they can be mostly Eastwards, but at 800km they're nearly all North- or Southwards. Their number makes them well known to astronomers, because they're brilliant in instruments. Some models (Iridium constellation) are reported to emit flashes, allegedly because their surfaces reflect light directionally. I have also seen Mir getting extremely luminous (no more comparable with a star!) as it passed over my head when Jean-Pierre Haigneré was on board. Solar sails (big things) have been proposed to illuminate by reflection work sites in far northern latitudes during long lights. ----- I believe - take with caution - that some spy satellites have lights to improve nighttime pictures of Earth. This would be technically easy, so it's probably done already. I may have seen one in action, but this is speculation. Consider an airliner light: it draws 200-300W electricity, easily available on a satellite; from 30km distance it appears extremely brilliant from the landing strip during plain daytime, and professionals report seeing these lights from 200km distance, which is already the altitude range of observation satellites. Since CCD cameras are very sensitive, such a light must easily suffice to replace the Moon when needed; an airliner light must be far too strong and noticeable for that use, so I expect they use less powerful ones. -

Linear Friction Welding (LFW) pushes strongly against an other the parts to be welded and shakes them sidewise until heat and movement forges them together, without melting. http://en.wikipedia.org/wiki/Friction_welding#Linear_friction_welding To weld, the shaking actuator must bring many kW over <1mm amplitude hence is quick, like 50Hz to 100Hz - more would supposedly be better. 100Hz is uncomfortable for the present hydraulic actuators; electromagnetic actuators first used are uneasy with the power. Starting instead from a rotation would permit to store energy for quicker release (this improves the weld seam) and use a higher frequency. 30kW*3s need few kg flywheel. A crankshaft can transform the rotation in the shaking motion, but to assemble the parts accurately, the amplitude must decrease to zero at the end. I suggest to revive the Stephenson valve gear for that. Here Emoscope's illustration, gratefully pinched at Wiki: http://en.wikipedia.org/wiki/Stephenson_valve_gear (click to see the picture move) The slide between the two rods is moved sidewards to adjust the amplitude of the top part, down to zero at the center. Here at a truss, it seems better to shake only the tube's free end and hold the truss node steady, so only one eccentric is really needed - with good balancing and adequate design at the slide, like adjusting the amplitude by sliding the arm's base rather than the connecting rod. The machine could catch the tube's end with one arm shaken by the slide and the node with a steady arm, connected preferably close to the crankshaft. Other uses may have two shaking arms of opposed phases, possibly driven by the same slide of proper design. One part or both can also receive crossed movements, say orthogonal and in phase quadrature, to shake with a circular motion that makes a more uniform cylindrical weld seam. Two crankshafts well phased, with at a part two arms converging perpendicularly to an other, achieve it. Other designs are possible. A crankshaft with eccentricity varying continuously along the axis, plus a de-biassing part, looks fragile to my eyes. A cylindre with eccentric hole that rotates around the crankshaft's handle and whose phase adjusts the amplitude is sturdy but not obvious to control. Easier: the rotation axis is parallel to the shake, a tilted disk transforms the movement, its inclination adjusts the amplitude. The Stephenson valve gear is well-proven. Its parts, movements and forces are sound. Marc Schaefer, aka Enthalpy

-

http://www.scienceforums.net/topic/69084-suggest-a-topic-for-master-thesis/ http://www.msfn.org/board/index.php?showtopic=129474 http://www.scienceforums.net/topic/67093-mscs-thesis-idea/page__view__findpost__p__700173 http://www.scienceforums.net/topic/68796-need-some-ideas-for-a-project/ http://www.scienceforums.net/topic/68996-compression-on-cuda/ http://www.scienceforums.net/topic/68781-i-need-suggestion-regarding-my-master-thesis-topic/ http://www.scienceforums.net/topic/75709-advise-help-forthesis/?p=749479 Very varied difficulty! Have you been programming for the past 10 years as a hobby, or have you had 50h course?

-

Parallel or anti- to the propagation are not the only possiblities! A photon can have a straight polarization also, like vertical, or horizontal, or biassed. This is just as fundamental a base as circular polarization, including for one single photon. Or the polarization can be elliptic. It's just that elliptic polarizations are less simple to make orthogonal, and one would have to tell how much elliptic. ----- A linear photon can be detected by a circular receiver, either left or right. Similarly, a circular photon fits a linear detector, either 17° or 107°. The photon has just 50% chances when it "decides" at the detector, instead of 0% or 100% if the nature of the polarization matches. ----- Same picture with atomic orbitals. A 2p orbital can be doughnut-shaped, with the wave's phase turning 360° per geometric turn (360*1=360, quantum number=1), hence a circular polarization. Or it can be peacock-shaped, with the wave positive at one side and negative at the other, hence a linear polarization. This is just for the phase of the time-independent part. Multiply by some exp(j*w*t) depending on the energy (...which is not absolute). Just like photons, a peacock 2p is a 50-50 sum of right and left turning doughnut 2p, AND a doughnut is a (phased) sum of N-S and W-E peacocks. Both are equally "fundamental". Better: if the transition is from or to an s orbital, the superposition of p and s has the corresponding polarization, and so does the photon. ----- To conserve the spin, an electron can flip - or rather it can change its orbital. A sum of orbitals is a strong electric current that couples well with a photon. ----- This story of straight being as fundamental as circular gets fun if you consider entanglement, because entanglement working equally with both is the kind of arguments that defeats theories of hidden variables. If photons decided their polarization when emitted, and not when detected, then the correlation would work with one kind of polarization only.

-

Photoelectric effect and conservation of momentum

Enthalpy replied to BearOfNH's topic in Modern and Theoretical Physics

The photons' momentum is very real and tranferred to the absorbing medium, or more to a reflecting medium. This "radiation pressure" is perfectly observed on spacecraft - it's most often the strongest parasitic force and torque that act on them. Many telecom satellites have special surfaces at the ends of they Solar arrays to stabilize the craft's orientation and save attitude-keeping fuel instead of wasting fuel from an uncontrolled radiation pressure. Near Earth the incoming pressure is 4.5µPa. Several spacecraft have used it for their propulsion, not just attitude control - but as a demonstration up to now. For these Solar sails to become good, they must weigh like 10g/m2; that's easy for the plastic film, not obvious for the booms that hold it - and damned difficult for the payload that demands huge areas, like 1 hectare for just 100kg. That's the challenge. Build huge, launch in a rocket fairing, reliably deploy in space, which I interpret as "test on the ground" hence in Earth's gravity. Solar sails can go in any direction but work much better nearer to the Sun. Very high energy missions like a polar Solar orbit (Ulysses spacecraft), a Mercury orbit, or joining the heliopause would be better with Solar sails http://en.wikipedia.org/wiki/Ulysses_(spacecraft) provided we invent the technology. It doesn't look very difficult, but space agencies (except Jaxa) do a very modest effort; several clubs promote them and bring solid inventions. -

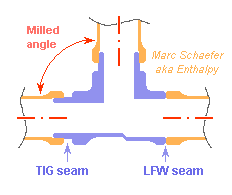

Trusses of shorter elements exploit slightly better the strength of a material of given stiffness. At the Esc-B sketch of message #38, two stages of 0.65m height would fit at each torus, and three around the ellipsoid's equator, with 2*30 tubes at each stage. This fits the capabilities of magnesium AZ80A; it also exploits better the aluminium AA7022, which is then as good as magnesium and more comfortable. Titanium is still uninteresting at this scale. Global buckling of the truss puts a limit on short (hence narrow) truss elements. I estimate it by assimilation with a uniform cylindre of same stiffness per length unit: only F=0.68*e2*E according to my experiment - simple theories are knowlingly false. I could not misuse Gerrit Wolsink's free "Framework" software to determine a truss' buckling; I plan to try with Frame3DD, and would gladly read proposals. ----- 1600 tube ends take long to weld. Turned tubes and separate milled nodes ease it and give extra thickness to the weaker weld seam. The tubes are turned to the proper thickness, leaving more near the seam. The inner diameter can be machined more accurate at the ends. The length is very accurate, the end faces as well. CNC milled nodes are affordable, light, and fit accurately the tubes' directions - the sketch is simplified, there would be six non-planar directions in a simple truss. They accept tubes just turned. Maybe some material at the center, plus a hole for one big screw, can hold the part when machining it. For Tungsten Inert Gas (TIG) welding, the groove at the sketch's left is a big help: it protects the back side without argon there, defines well the weld depth, and a shallow shoulder places accurately the tube's end. Linear Friction Welding (LFW) gives stronger seams, at the sketch's right. Can the truss be bigger than the welding machine? How shorter, and how accurately shorter, are the parts afterwards? To be checked. With the same parts shape, laser welding could be made portable and automatic. ----- If the skin is discarded by molten wires as suggested in the previous message, Ti-Al6V4 offers 828MPa, 7W/m/K @RT and 1.7µohm*m - a strong candidate that can be zapped by a 3V accumulator and semiconductor switches. Though, I prefer the electric motors. Marc Schaefer, aka Enthalpy

-

PU then. It's also more compact for the same energy than an elastic material. Different hardnesses exist, but apply badly to computations at shocks, because speed changes radically how elastomers behave, and because we use them in a nonlinear mode. One has to experiment, with fast cameras or accelerometers.

-

Photovoltaics vitally needs converters. Fast-charge batteries exist and are little worse than slow ones: have a look at a store for model hobbyist. Quicker car operation just replaces the empty battery with a full one, so the car doesn't wait.

-

You have to decide if you want to absorb the shock or to rebound. As a strong absorber, polyurethane is the best - though Viton for instance rebounds less.

-

50Hz or 60Hz transformers are still the state of the art from medium to high to medium to "low" 230V voltage. No-one considers to replace them by electronics and smaller transformers up to now, unless the transmission through sea or huge distances demands DC. Since most electricity uses at home are light bulbs, I doubt DC would be sensible, even if there were no compatibility issues. Even to supply current very locally, 50Hz transformers are used. Within a school, a plant... If 1MW consumption is spread over 200m, you typically have a 24kV transport and one or two transofmers to 230V. So if you imagine a new small city powered by Sunlight far in a desert, it will have several voltages, preferibly with standard transformers between. Worse, imagine when the city grows... Electric motors for sure. Squirrel cages run so well! Some fluorescent lamps and many halogens need AC. Some older power electronics needs AC: thyristor bucks for DC motors, cycloconverters... One more: electrocution is much worse with DC. AC leaves you more chances to survive, since the muscle tetany isn't so radical. I survived once to 110V 60Hz under very bad conditions; with DC through the thorax I'd be dead.

-

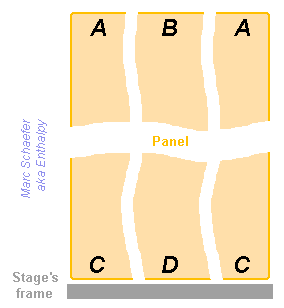

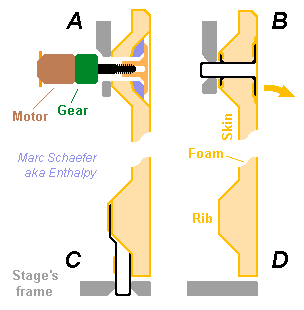

A launcher would separate the panels covering a stage above the atmosphere and during a strong acceleration. These favourable conditions permit to topple the panels to separate them. This script is cleaner, and it also tolerates better a few malfunctioning motors. A pin defines the vertical and lateral position at the panel's top center B, two geared motors and screws the radial one at the top corners A, two pins at the lower corners C the radial ones plus at only one corner the lateral one - the other hole at the stage's frame being wide. As the motors release the upper corners, springs (not sketched) push the panel's top outwards and the upper pin disengages, while the lower pins are still engaged, toppling the panel with the help of the acceleration. The panel falls to contact at D and, because the panel is curved, its rotation raises the lower corners and disengages the lower pins. The panel separates completely. This worked properly at Mach 1.3 through the lower atmosphere. I had B and A functions at the top center with a wide flat contact, and only one C at the lower center, further inwards. Here with big panels of limited stiffness, I prefer more A and C despite this can strain the panel; one can even design the curvature to apply the panel against the frame at B also - or have a single A at the center. A's and C's can be at 1/5 and 4/5 of the width for instance. Shape memory actuators - much smaller than for payload separation belts - are possible replacements for the geared motors and screws. Or even, wires burnt by an electric current. Marc Schaefer, aka Enthalpy

-

Carbon fibre is exactly what one should avoid to absorb shocks. Glass fibres aren't good neither. You might try aramide fibres, but they're good only to spread a very local impact as a bullet-proof vest. The real material to absorb shocks is polyurethane. Most resistant, little rebound. If for some reason its shape does not fit you need, you may try a polyamide rope, but it absorbs only one shock through irreversible strain. Instead of a material, you may consider a component called a hydraulic shock damper. Highly predictable, more compact than polyurethane.

-

Be careful: http://en.wikipedia.org/wiki/Nitrosamine#Cancer ---------- Would you like instead to make fuels from isoprene obtained from latex? If you achieve a head-to-tail trimer or tetramer of isoprene, then hydrogenate it, you get farnesane and phytane, which would be very nice as rocket fuels (better phytane then), probably also as transformer oil, vacuum grease... http://www.chemicalforums.com/index.php?topic=56069 (you must log in to see the images, and beware I changed my mind after writing some messages there) The outstanding freezing point depends fundamentally on head-to-tail oligomer. Beware pristane is dangerous and shall be excluded. More difficult, farnesane would be a perfect replacemet for aeroplane's kerosene, but kerosene is so cheap... One US company wants to produce fanersane from bioengineering methods through the diphosphate route: I suppose an isoprene trimer - with the proper catalyst - is easier.

-

I achieved about 0.02 static friction at a screw+nut with the proper lubricant. I've never read a lower value reported. What do you mean by "perfectly cutting"? "Flat" for instance doesn't essentially reduce friction. Plastics even rub less against a somewhat rougher metal. If you guarantee a minimum speed, then hydrodynamic bearings can achieve an extremely low friction. 0.001 is realistic then. Or use ball bearings.

-

Many things go the wrong way in your theory attempt, like the cos which is wrong, or the trailing areas - the make much drag at subsonic flow. Rather than discussing dozens of points, I suggest that you first read a book about experimental aerodynamics. A good old book with experimental graphs and formulas, not the useless differential equations. Then you'll have the observation basis needed to make a theory - or avoid making one.

-

You have to compute the density of the ejected matter, its speed, and then the mass flow per second gives you the section. At the throat or at the exit - just take the local conditions. Density results from pressure, temperature, composition, and these are not really accessible to hand computation. Take a rocket computation software like CPropepShell or RPA. 200 looks much for a rocket in the atmosphere.

-

If your planet resembles Earth, the speed on low orbit is near 8000m/s. Crashing from a low orbit take a minimal brake, like 50m/s only. The ship gains some speed by losing altitude, it's like 200m/s. Put together, you can take the orbital speed as the impact speed, which is then nearly horizontal - unless the ship made a hard manoeuvre that takes very much propellant with present human technology. 1000m/s downwards is reasonable for 100km height, but this would demand to stop the 8km/s orbital speed first.

-

It is commonly used by research, and to some extent by diagnosis and therapy. http://en.wikipedia.org/wiki/Transcranial_magnetic_stimulation http://www.scienceforums.net/topic/70203-transcranial-magnetic-stimulation/ When researchers want to halt temporarily and locally the brain activity, they have to adjust the intensity of the field. A stronger field provoques seizures. Such machines are in the near-cubic-meter volume, but I believe they can be much smaller (second link above), and that they have been transformed into weapons of very few meters range to let people fall and hurt themselves. Aimed at a car driver, they could cause death.