-

Posts

3887 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Everything posted by Enthalpy

-

Present-day electron microscopes show individual atoms, even 2-3 atomic layers below the surface. Fabulous. Recently they showed the displacement of an atom as a ferroelectric ceramic like BaTiO3 is polarized. They don't show the composition of the atoms.

-

1) Engineer's answer: µ is important because it's near 10-6 so you better don't forget it... Half-joke only, this happens from time to time, and because many design attempts with electromagnetism yield completely impractical figures, intuition doesn't always tell if it results from a mistake or because the goal was impossible. µ represents the ability of the medium (including vacuum) to let the induction B go through easily. That is, B=µ*H. µ is often written as µ0*µR, or vacuum times relative permeability. H is often costly (current, size of permanent magnet) while B is often the desired effect, for instance to produce a voltage; then a big µ is desired. 2) If you have a magnetic circuit, which is generally the case, or if you magnet has a permeability µR>1, which was the case with AlNiCo, then you're sitting in the ink (as they say in German) to hand-compute the induction. That's a job for FEM software. Present-day ferrite or Nd-Fe-B magnets have µR~1.1 so you might take 1.1 and, without an external magnetic circuit, the situation looks better. You only have µ=1 everywhere, and a portion of the Universe is magnetised. Then the magnetisation J coupled (vectorially) with 1/R3 gives you H or B; you can sum the contributions of all volume elements over the magnet. J itself can be modelled as many tiny current loops, and then you can compute H from this current (using a formula for a loop, not a straight wire). It does even make some sense for the magnetic polarisation resulting from orbital moments, where the evolution of the electron's wave function's phase over angle and time has some attributes of a rotation, especially angular momentum (electron's mass) and magnetic ommentum (electron's charge) - but not other attributes, for instance the electron's probability of presence doesn't move, and the orbital doesn't radiate. 3) Static charges versus "moving" ones... Except that the spin produces a magnetic field without a movement. 4) Current in a conductor is a collective behaviour of electrons, the atomic scale isn't adequate. Electromagnetism is never basic, for no-one... One has to develop his intuition despite electromagnetism is not intuitive. Qualitative understanding can he horribly complicated, in antennas for instance.

-

The thermal power given is for zero temperature difference, for which one wouldn't need any module. That's why Peltier modules are bad candidates to cool Cpu. People who want a Cpu cooler than the heat dissipator use a standard cooling cycle like in a fridge, or have a stock of liquid nitrogen. Peltier modules are seducing where little power must be removed and vibration free operation is better, for instance at the sensor of a camera.

-

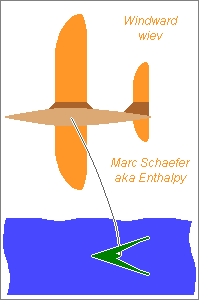

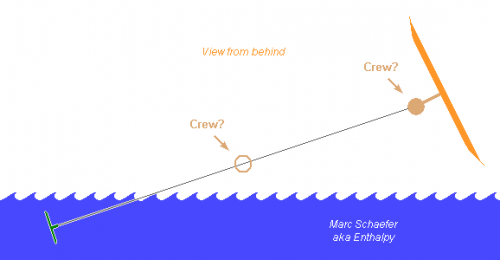

This is the windward view : Both the sail and the centreboard are stiff to reduce their drag ; they should also have a more benign behaviour at high speed. Notice both can orient themselves freely around the cable hook and have their own stabilisation, as inspired directly by the historical Greenbird http://www.greenbird...ecord/the-craft Yaw and roll stabilise as at an aircraft, but due to the cable and the two linked foils, pitch stability may require a new theory. To be clarified before putting people on board. Cavitation is a difficult issue at the centreboard and should, sincee lift forces are equal, induce a higher drag than at the sail. Maybe the same shape as the sail can be made to work; but on this sketch, I represent an attempt with a highly swept wing to avoid cavitation. This is done at race boat propellers and at feeders for centrifugal pumps. As drawn here, cavitation at the cable won't neither disrupt the action of the stabiliser (the wing's tips). A different option would leave the wing's extrados cavitate fully - must be less good. A profiled cable, as on aeroplanes, would drag far less than a round one... You find out how to prevent fluttering then. Many small stabilisers behind the cable, spread along its length? Steel would make a narrow cable that drags little. Lighter polymer fibres can optionally be put parallel and impregnated to make a somewhat flexible cable; a company called Cousin then braids more fibres around them to protect them, hold them together and press the excess resin away. Marc Schaefer, aka Enthalpy

-

Thermolysis of water from burning hydrogen

Enthalpy replied to njaohnt's topic in Inorganic Chemistry

It does. That means oxygen+hydrogen combustion is always incomplete where it occurs. As heat is used - for instance to accelerate the produced gas in a nozzle - and the temperature drops, the reaction completes. In a rocket, you would add an excess of lighter hydrogen in order to use all the heavier oxygen - and even a bit more hydrogen, because the rigid diatomic hydrogen molecule expands more efficiently in the nozzle than the triatomic water. (Nothing to do with bearable temperature as some books allege). Similarly, a hydrocarbon+oxygen flame can't produce only CO2. In a decent rocket, you get 50-50 CO. This is an excellent reason to increase the chamber pressure of a kerosene engine, as CO2 produces much more heat than CO. This excellent reason adds to the more efficient nozzle with the bigger pressure ratio. -

Big nozzles weigh a lot. This is an other limit, in addition to flow stability in the atmosphere. The RL-10 pushes 100kN in D=2.15m so (as chamber pressure improves this very slowly) a Vulcain with 470s and 1.4MN would need a ~14 times bigger area or D=8m, both impractical and too heavy. For comparison, Saturn-V had huge D=3.8m nozzles at the first stage, and this is more or less what solid boosters have at Ariane-V and the Shuttle, where mass is a small worry.

-

Hi Bob and everybody! Depending on whether I got properly your intent of gravity assist at Earth, it might be flawed. The simplest representation of a gravity assist is to think it first as seen from the celestial body: the craft arrives at some far velocity and later moves away with that same velocity but in a different direction (meanwhile it has been faster as it was closer to the body). Then, seeing the flyby from a different location, say from our Sun, what was "same speed, different direction" can become "more speed" (or less speed, very useful to capture a craft using Saturn's moons) if the directions subtract the celestial body's speed first and add it later. Now, a craft starting from a Lagrangian point or the Moon moves essentially with the same speed as Earth does before nearing it, and will regain this nearly zero speed vs Earth as it moves away. No gain possible, because no initial speed difference is available. The craft will depart with the same 30km/s vs our Sun as Earth has. One trick of fuel depots at Lagrangian point is not a slingshot effect but an Oberth effect (Wikipedia): the craft gets free 11km/s from Earth, it accelerates there, and loses speed as it leaves Earth's vicinity - but this is more efficient because it's all a matter of energy vs speed. That is, 3km/s near Earth bring (11+3km/s)^2 of which 11^2 are lost, instead of 3^2 if accelerating far from Earth. ----- Aerocapture at high speed must be possible at Mars but needs a craft with some lift. Please refer to our other forum, I described it there - maybe in the X37 thread. ----- A Venus flyby would make the trip longer because of distance, and Venus doesn't permit a slingshot at high speed because it's only as massive and big as Earth is. Repeated use won't help. Worse, reaching Venus takes a higher delta-V than Mars. Venus slingshots have been used to obtain decent speeds from very low initial speed, both to reach Jupiter (or Saturn?) and Mercury. ----- I couldn't find a straight-path travel to Mars, far less so with chemical propulsion. My best results (other forum) were a short trip OR a short stay (near opposition) with chemical propulsion and high-speed aerobraking both at Mars and Earth plus descent-ascent and return modules preset at Mars, and a short trip AND a short staywith Solar thermal propulsion and preset modules. Both use a trip passing nearer to our Sun than Earth is; I put a downloadable spreadsheet there.

-

I confirm the very few % efficiency, like 2%. 5% is already better than what I used long ago. The theoretical limit is that electrical conductors that link the contacts of different materials need a section to reduce ohmic losses, but then they carry heat as well. Metals have the least bad ratio of heat-vs-electricity, but semiconductor offer a larger thermoelectric voltage and a less bad. Superconductors aren't used there (even at suitable temperatures) despite low heat conductivity; I ignore why.

-

Hello to all sailors, record chasers, and enthousiasts in general! The thingy sketched below is meant to be a sailboat - at least to the sense that wind moves it - and to be fast. The sail, high in the sky like a kite, resembles essentially a glider. The centreboard, fully immersed, resembles a glider as well. A thin cable, possibly of steel, binds them. Said sailboat has no hull at the surface: only the cable cuts through the surface, meaning a tiny drag there, and the ability to sail through rough sea and deep water. On the other hand, the need to control actively and permanently the sail and the centreboard intend this boat for artificial records only. As the cable's angle tells, the lift can exceed the boat's weight many times, an other factor for speed. I expect the centreboard to be set to drift a bit, so both it and the sail pull the cable forward, instead of the sail pulling both. The safest option would replace the crew by a remote control, but one may want or have to put a crew on board. The centreboard is a bad location, even with an added hull, because of poor visibility and excessive risk in a collision. An added hull that floats when steady and is pulled in the air when navigating is one option. The sail is an other one, and then it resembles a glider a lot: the safest place to splash down if the centreboard is destroyed, but the most difficult to take-off - something unclear. The cable is longer than drawn, and the centreboard far more smaler than the sail. A sketch from the side is coming and should explain the shape of the wing and the centreboard. Marc Schaefer, aka Enthalpy

-

As an alternative, you can heat hydrogen with Sunlight and eject it. The specific impulse is around 800 to 1200s, which suffices for a fast Mars trip AND a short stay there (which chemical propulsion cannot both offer, only one or the other), and the concentrators and engines are lighter than a reactor - also avoiding other drawbacks. It's not an existing technology neither, but I put some figures on it and it looks reasonably within grasp - simpler than developing a plasma engine or a reactor. Zubrin's Mars Direct is a direct competitor to Nasa's choice of Vasimr, which "may" explain Zubrin's hard tone agasint Vasimr. His comparison with existing ion drives does not take into account the thrust magnitude. Existing ones wouldn't accelerate a huge craft in days. But I do agree no lightweight strong reactor exists, which is a condition for strong acceleration hence short trip. Anyway, I'm no supporter of Mars Direct. Pre-placing a descent-ascent module and a return craft in Martian orbit is a safer option, as it can offer redundancy and needs no trip at Mars' surface to some hopefully working equipment. Chemical propulsion allows a short stay there (2 weeks around opposition) if aerobraking at Mars and Earth - or less interesting, a shorter trip and the usual long stay. It involves passing nearer to the Sun than Earth is. Sorry, moderators here don't want links to my descriptions in an other forum, which Google doesn't list neither.

-

You mean such waves http://en.wikipedia.org/wiki/Soliton ? It needs a nonlinear medium, so how does your plasma behave?

-

Do you really need to electroplate? Silver plating on copper (at printed circuits) is done by dipping the metal into a silver salt solution, without current. Did I miss somehing, like the plating thickness maybe?

-

There page 18, reference from 1974. http://www.nndc.bnl.gov/nndc/stone_moments/nuclear-moments.pdf It was a Web illusion: 1000 sites copy their data from a single one, so your data was absent from 1000 sites.

-

If you hope to see a nucleaus with 8 protons and 1 or 2 neutrons, it's no, it doesn't exist. I'm not quite sure if these many protons would hold together without many neutrons... Standard theories tell the attraction force between two protons is essentialy as big as between two neutrons or between a neutro and a proton. But then, no di-neutron nor di-proton has been observed, which might maybe perhaps suggest a force only between neutrons and protons. Do we have direct access to individual forces between baryons? It seems all models result from indirect observations of complete nuclei. One excellent reason against 8 protons and few neutrons is beta radioactivity. Protons would just emit a positron to convert into a neutron, so the nucleus would have about as many protons and neutrons, which is much more favourable. At such light elements, just two neutrons in excess or default result in a very short-lived isotope. This nice site contains, among others, information about isotopes: http://www.webelements.com/ and here are the isotopes of oxygen: http://www.webelements.com/oxygen/isotopes.html 16 to 18 are stable, but 15 and 19 live around 1 min.

-

Gathering figures (too) quickly about the HM7B, I get 65kN thrust for 15+5t load, or 0.3G. This stage's mission is to attain Gto, so it could ignite some 3km/s before having Leo energy, similar to your configuration. Something special to Ariane is that it doesn't shut off before joining the Equator. The upper stage burns very slowly while it loses altitude initially. This is possible because Kourou is at 3° only and because the lower stages are programmed to give a higher altitude than the perigee.

-

1.0 kg of burned coal releases 33 MJ (millions of Joules) not 33 mJ (thousandth of Joule). It may all look easy, but even after years of unit conversions, engineers and physicists still forget to convert hours into seconds, kilograms into Newtons... Maybe the most frequent source of errors.

-

Hi Bob, that's Marc, nice to see you here! I appreciate your efforts at Ssto, am myself convinced they're feasible, less so that they're better. Anyway, one difficulty I haven't seen you address (or did you?) is the need to throttle the engines at an Ssto. If one single stage ends 20 times lighter than it starts, the initial 1+0.4G end as inacceptable 28G. For instance the Vulcain has no throttle possibility as far as I know. Even starting with 3 engines and shutting 2 off would leave 9G, too much for the passengers and the structure, and this would need a separate roll actuator since Vulcain has none, alas. The RS-68 and RD-0146 would provide roll control (but not the J-2X, damnit). Some kerosene engines offer throttling, the RD-170 down to 37% (or 40% from other sources), but a kerosene stage needs an even higher mass ratio which worsens this difficulty. This gives a clear advantage to the RL-10, which has been demonstrated to operate properly at very small thrust. ---------- In the SLS design I see six RL-10B to push a second stage weighing 350t, is that it? I feel the resulting 0.2G don't suffice. Existing launchers get >0.8G from a full stage, even a third or fourth one. A very smooth acceleration is good once the craft is already in orbit. ---------- Nozzle exit diameter costs room and mass. At a typical RL10 or Vinci mission it may bring 300kg more performance but cost 150kg. Going further would negate any gain. That's an excellent reason for high chamber pressure even for upper stages. ---------- On an other forum the guys willing to mine asteroids were looking for ideas from the participants, and apparently they had none by themselves - the suggestions they tested at the internauts were complete nonsense. Until I see convincing figures and designs, I consider this move to be a crook. Take any impossible idea with high promise, ask for suggestions on the Internet, sell this to a billionaire. Just like the propagating wave breeder sold to Bill Gates. Oh, and, is there any platinum on the Moon? Up to now we've found sand, iron, aluminium, plus traces of semi-banal things, but no single ore of anything I'm aware of. Wouldn't you prefer to send space tourists there?

-

(1) Use carbon composites where you had not dared it before. Pray that the crash investigators find an other culprit. (2) Compute the loads with a CAD, reduce all margins, check that judges haven't condemned someone for this before. (3) Use better alloys or assembling techniques. Check that their weaknesses aren't known at the time you use them, so you wont' be hold for responsible. Well, it's a simultaneous effort at materials, design, and everywhere. For instance, if you find a welding method (stir welding) that works for Al-Cu or Al-Zn alloys, you get both the better material strength and the better assembling technique.

-

Possible sources of error in fatigue testing?

Enthalpy replied to VelocityGirl's topic in Engineering

Fatigue is non-reproductible is this will overshadow the experimental errors. The materials' fatigue behaviour depends heavily on the skin's chemical and thermal treatment (nitride, carbide, quenching), which is imprecisely known, and on the skin's roughness. Especially, final grinding parallel to the stress (axially in the drawing above) improves a lot. I'd suggest to document at least the superficial hardness and the roughness. -

Why is the Stirling Engine Not More Widely Used?

Enthalpy replied to jimmydasaint's topic in Engineering

The Stirling engine has reciprocating pistons, hence it is big, heavy, and it vibrates. Turbines are better in all these aspects. The only advantage of a Stirling over any other design is its heat exchanger which works on one single side of the solid hence can use a fine powder with a big exchange area with the gas. This improves operation when heat is available at a moderate temperature. But design a good (=efficient and compact) heat exchanger and any engine will be as good as the Stirling. It's less easy because you exchange heat between two gases at different pressure, hence need tightness. Easier if your fluids are clean, for instance a closed-loop gas turbine heated by Sunlight. Anyway, the Stirling still exists just because it's a bad habit from renewable energy guys. -

Every recent wind turbine has a converter to avoid the need of synchronization with the power grid. Some Darrieus have three blades and this would be MUCH better in the geomagnetic field since the produced power and overall torque would be constant over one turn. Though, the torque on each blade would still cog! Two maxima per turn. Acceptable since torque by teh wind also cogs at a Darrieus. In this three-phase case, an AC-AC converter typicaly has one resonance converter per input phase (or phase pair if delta operated) so the current it draws is a sine in phase with the voltage: this gives smooth operation. The DC sum of the three outputs is constant (three pulsed sin^2 at 0°, 120°, 240°), and so is the torque at the shaft. Then, DC is converted to the power grid three-phase. A much simpler six-phase rectifier would be less good, as it lets the DC current flow through each of the three generator outputs for 1/3 of a period in one direction, idle for 2/6, and for 1/3 in the other direction. Not bad, but the pulsed current creates some mechanical cogging, the output voltage also fluctuates a bit, and you still need a DC-DC converter to stabilize the voltage. The puzzling idea of geomagnetic operation can be compared with a separate generator. Earth's horizontal induction can be 0.4G=40µT for instance, so one blade sweeping a half-cross-area of, say, (2/pi)*h60m*R20m cuts a flux of 0.03Wb only. As little as a separate generator with 1T mean gap induction and just 0.03m2 cumulated pole area. Then this flux varies a slowly as the Darrieus rotates. Take 100m/s blade speed, it's only 0.8Hz, giving a peak induced voltage of just 0.15V per coil turn. A separate generator could have 48 poles to create comfortable 19Hz and 24 times more voltage per coil turn. The copper cross-section you would reasonably put in the Darrieus isn't bigger than what a separate generator accepts, and the longer windings mean more copper losses and hardware expenses. That's why electric machine design tries very hard to maximize the flux within the minimum size. The Gramme design was a fabulous improvement, it hasn't changed since then... So: the coils in the blades are not quite as good, and they concentrate more engineering constraints on fewer parts. For wind turbines, you might give a look at my "electrostatic alternator" (Google together with "Marc Schaefer", follow the links, begin at the drawings). At these slow generators, the design with an insulating liquid is smaller and more efficient than an induction machine; it could be overall better.

-

You get the maximum efficiency only for one blade pitch, so only generator loading could keep the turbine at maximum efficiency. This is done by the conversion electronics. At the paleo-windturbine-era, when generators were coupled to the power grid without electronics hence had to be synchronized with the frequency, blade pitch had this function. Now it's used to protect the turbine from overspeed in a gale. No need for a huge shield. One Spanish company varies the pith individually without one rotor turn to reduce vibrations and pitch moment. Some older but sound designs had a fixed pitch and a small tiltable area at the tip of the blades, which served as an aerodynamic brake. Very efficient, because braking the rotor lets it stall, which reduces the lift a lot. Essentially, a turbine running normally catches as much force and power as a complete disk (costing less material) but when stalled, it catches as little as non-lifting blades.

-

Air speed isn't directly the input that decides if a foil fits your use. Reynolds number is more important. Plywood sold for aircraft construction guarantees some minimum strength, allowing to compute a beam much like is done for metals. It seems you don't have the necessary knowledge to build your aeroplane. Either learn it, or let knowledgeable people design you craft, or build your craft according to existing drawings - that's already difficult enough. Many almost-finished aeroplanes can be acquired from amateurs who give up. Cheap, saves time.

-

It takes much power just to keep a helicopter in the air, even without losses here: Lifting force is (worse than) F=ñ*V Power consumption is (worse than) P=ñ*0.5V^2 where I misuse ñ for the mass throughput in kg/s and V is the down speed after acceleration by the rotor (supposed zero upstream, or subtract the upstream V and 0.5V^2) Because of V and V^2, a small V and a big ñ (through a big rotor area) need less power for the same force, as said ewmon. This holds for horizontal propulsion as well, but here air speed before the propeller limits the exaggeration: once the relative speed increase is small, the game is over. Though, the trend is toward bigger propellers to be efficient: just compare recent airliners with the B-707. Unducted fans and others are attempts to make propellers larger than a turbofan. Turboprops are preferred on slower aircraft for being wider. And two-flow turbofans result equally from this logic. The same reason tells that magneto-hydrodynamic propulsion (MHD), which prefers very fast flows, is inefficient at slow boats.

-

Yes! It can change the grain size, make the grains elongated, define their orientation. Laminated alloy products have different properties in the lamination direction. That's why the yield strength uses to be measured in the transverse direction. Even when warm-rolled: transformer cores have one better magnetic axis because of lamination orientation; manufacturers often desire this effect. It can change the crystal lattice. That's common with austenitic stainless steel. When little nickel (17%Cr+7%Ni) leaves the austenite metastable, cold rolling transforms it partially to martensite, which helps hardening and also makes the alloy magnetic, as can be observed on stainless screws. Where much nickel (18%Cr+12%Ni) stabilizes the austenite, very little transforms to martensite and the alloy stays nonmagnetic - but it does harden though needing more deformation, so martensitic transformation is NOT the whole picture. Almost any alloy hardens by cold rolling though keeping its lattice, for instance Al-Mg alloys, unalloyed copper... Very few metals keep soft despite deep deformation. Gold is the best known and can be squeezed to ultra-thin foils; very pure (ppm) aluminium hardens little. Some alloys are designed to harden during cold draw: the mentioned 17-7, the old X120Mn12, all alloys for stainless springs... Cold draw can be followed by heat treatment, often a precipitation hardening, like in Cu-Be2, stainless spring... 10mn in a kitchen oven at 200°C improves both the strength AND the toughness of cold-rolled 17-7, which I suppose isn't precipitation hardening. The effect is more important with polymers. Only fibre stretching at production makes polymer yarn, fabrics, ropes resistant. Here it's directly an effect of molecule elongation and orientation.