-

Posts

3887 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Everything posted by Enthalpy

-

The estimation of casualties result from 85Kr that does not accumulate in bodies, as stated. Storing noble gas is done every day, for instance in bottles used for arc welding. It wouldn't require to reconfigure the reprocessing plant. Storing 85Kr leeds a few containers of moderate size. Which is also incomparable with cars, which do bring some serious benefits as opposed to a poison in our atmosphere. As for the cost, I dare to maintain that several dozen lives are worth a few bottles. Unless you find an arguably better model, this figure results from prudent and mainstream evaluation methods. And how much money is spent to rescue a hostage in Colombia, or victims of an air wreck? Would you answer them "better spend my money elsewhere"? Or are they more important because they have a name and a face?

-

Krypton-85 85Kr is a beta emitter with 687keV maximum energy and 10.7 year half-life. It's produced by uranium fission with 0.27% yield (137Cs and 90Sr: 6%). Here a report, a bit old and in French, but figures read the same in English anyway. 85KrIpsn.PDF When reprocessing used nuclear fuel rods at La Hague, solid fission products like 137Cs and 90Sr and separated for storage, but 85Kr is just diluted and emitted in the atmosphere. For instance in 1999, La Hague emitted 2.9*1017 Bq of 85Kr, more than the radioactivity of 137Cs and 90Sr released by the Chernobyl disaster. Iodine, caesium, strontium radioisotopes fall on the soil more quickly and locally if emitted, and accumulate in the food chain. Krypton, as a noble gas, dilutes in the whole northern hemisphere's atmosphere, where in 2001 it added 1.2 Bq/m3, with 3/4 of it coming from La Hague - it must be worse by now. How bad is such an added radioactivity, much smaller than natural sources anyway? It irradiates a human body by 4nSv/yr, or 500nSv/yr at the skin as beta rays don't go deep. No experimental data tells the effect of such a low dose; scientific near-consensus is to extrapolate proportionally from higher doses, taking 1% more risk of a fatal cancer per 0.2Sv exposure. Over 30 years, this adds only 6*10-9 risks of casualty - but for each of the 6 billion people in the hemisphere, meaning an estimated 36 casualties. Note the 1% per 0.2 Sv is a whole-body average, but external beta rays damage essentially the skin. It seems that 500 nSv/yr at the skin is a bit worse than the deep 4 nSv/yr taken here. Some people challenge that the risk is proportional to the dose; they want to see some dose threshold below which the risk vanishes. Among them is Areva, the operator of La Hague. I consider that since 85Kr arrives from the power plants confined in fuel rods, keeping all 85Kr confined in some storage can't be that difficult. And to avoid three dozens possible deaths, it should be done, without arguing about risk models.

-

You work against the attractive Van der Waal's force to bring a molecule to the surface, and this added molecule increases the area of the liquid. The ratio between the added work and the added area is the tension. Molecules go where they're attracted to, or in other words minimize their energy, by diving into the liquid where they have more neighbours. By doing so, they reduce the liquid's area.

-

Typical efficiency values for concentric heat exchangers?

Enthalpy replied to VelocityGirl's topic in Engineering

I must understand it wrongly... Nearly all heat lost by one fluid gets into the other. A tiny little bit of heat may flow into (or from!) the surroundings, but minimizing this is very easy. So what do you call efficiency? I expect other numbers to characterize an exchanger, for instance watts per kelvin, or the pressure drop... -

Fun. I had suggested rapid prototyping, whose first machines used UV polymerization of MMA, to make the frame on which catalytic nickel is deposited. But as this was almost four years ago, I had forgotten it. Getting old. http://saposjoint.net/Forum/viewtopic.php?f=66&t=2051#p23419 So the improvement by the Californian team is that - They made it! Not the same as a paper description... - Light seem to define long tubes directly along the beams. This differs from rapid prototyping. - They have some practicable means to remove the frame once nickel is deposited... Very nice achievement!

-

The kind of thingy that stimulates inventiveness, curiosity, and more... http://www.sciencema...nt/334/6058/962 Science Magazine is pay-for-view, alas, and reports elsewhere are very incomplete: http://latimesblogs....?track=lat-pick From what I read elsewhere: - This is a lattice of very small metallic tubes, made as a single part - Newspapers call it a material, which it's not in a strict sense - A frame of rods is first obtained, I understand by many crossed light rays that polymerize liquid MMA into solid PMMA - Catalytic nickel is deposited on the solid frame after liquid MMA is flown away - And the solid MMA frame is "somehow" removed from within the nickel hollow frame... Unexpected: - Catalytic nickel can be resilient, I thought it were always hard and brittle. - They get a very low bulk density from tiny tubes, implying very thin tube walls. I knew electrolytic nickel is used at 6µm wall, here electroless nickel must be thinner. ================================================================= If I see their truss properly, all tubes cross at 90°, which partly explains why the truss can collapse without breaking. Other uses would need a stiff truss, which could be obtained by more tubes directions (more light beam directions) like 30° http://en.wikipedia....iki/Space_frame provided light stray reflections don't play crazy then... ================================================================= How they remove solid MMA from within long narrow nickel tubes must be tricky... Has someone access to Science Magazine, please? I could imagine, as a liquid etchant, to use dilute hydrogen peroxide, but it can't be very fast. A solvent must be even slower. Or they first melt away the PMMA, then etch away the remnants. Gaseous operation must both bring the etchant and remove the products faster. Possibilities? - Ozone-enriched air? - Dilute nitrogen tetroxide? - Hot oxygen or chlorine at a very low total pressure. That must be fast. If the PMMA frame can be made hollow, that is of tubes instead of rods, by circling the light beam that polymerizes the MMA, then the remaining through holes would let etch the PMMA frame hugely faster. Marc Schaefer, aka Enthalpy ================================================================= And their trick with light beams looks like an excellent way to produce the heat exchanger I suggested there http://saposjoint.net/Forum/viewtopic.php?f=66&t=2051#p23419 I wanted to make the frame by winding something around pillars for instance, but light beams would define many small aligned rods at once, and they can be automated. Some rods would extend to the sides, but they can be cut away before nickel deposition. Nice! A little bit of MMA stkicking to PMMA and polymerized before nickel deposition would make smooth transitions between the rods, nice for strength and for flow. With different light beam diameters or by circling the beam, varied nickel tube diameters are defined, which is all-important to make a heat exchanger with much exchange capability combined with a small pressure drop - just like blood vessels have varied diameters. In a simple case, tubes would be wide in the X direction, merdium in Y, and small in Z. Imagine a square pattern in the YZ plane: you could have fluid inlets at even rows and outlets at odd rows. Or more subtle schemes to obtain counter-flowing fluids. Marc Schaefer, aka Enthalpy

- 1 reply

-

1

-

What you have to learn is that turbine efficiency refers to the available enthalpy drop, as computed from the available pressures, not to the input heat. And independently of any theory, existing thermal power plants have efficiencies like 42%, look for data. Yes, that's the kind of figures common in usual thermal power plants. Coal produces vapour at a temperature not much hotter than 560°C because turbine blades aren't cooled and though shall last for very long. Though, the whole plant achieves 42% efficiency, or even better. Which does require heat exchangers and pre-heaters everywhere. You mixed an average day/night output with a peak power. You still have to understand that radiation by the absorber is not at the same wavelength as the absorbed light, and emissivity depends on the wavelength. In addition, emissivity only multiplies the T4 dependency. Alone the Sun's 5950K compared with <900K give a factor of 1900. So : building a light absorber is easy if one needs only 600°C. Unless someone botches his job, efficiency is very high. As well, a tower with its more complicated mirror steering brings the advantage that light concentration can be optimum, as opposed to the simpler cylindrical or parabolic concentrators. 580km must be the longest underwater line. Aerial transmission between Itaipú and São Paulo is 800km long and both lines carry together over 13GW now. http://en.wikipedia....iki/HVDC_Itaipu Which is an admirable achievement, because they finished the lines in 1984 and designed them much earlier. At that time, no IGBT nor GTO existed. They made every conversion AC -> DC -> AC with diodes and gate turn on thyristors (SCR). Even longer, but with consumers spread over the length: http://en.wikipedia....nd_Transmission Bay James to New England, a long trip, several GW as well.

-

No, because the collector's temperature hence the wavelength differ from the Sun's surface. And even is absorptivity equalled emissivity, the T4 dependence would give >98% ratio. Figure that, I had such reasons to give the number. >40% is for existing complete thermal plants, which includes all the losses you imagined. By the way, on a power plant, the turbines have widely over 90% efficiency. Price does scale with the number os units. I don't feel the need to explain that. Compute it again.

-

I saw such a silver deposition on glass many many years ago, in a chemistry class. It was very easy, something like silver nitrate, freshly mixed with an amine or some reducing agent, at room temperature. Any solid surface, including the glass ware, catalysed silver reduction and produced the deposition. A known reaction. Unclear to me: how good such a silver layer is. It was mirror-smooth, and I believe mirrors were produced by that reaction very long ago. Dilute the reactants to deposit a thinner layer. I nearly suggested ITO... The one you want to replace. Annealing might improve - or not! I can imagine silver movement allows it to group into lands. Did you try to just evaporate the metal? When I evaporated aluminium with an electron gun, the film was translucent at the beginning, so thinner should be transparent. Keeping the target at moderate temperature might give a better uniformity. [iF you still find such an equipment! It was during the paleo-silicon era, at 6µm channel length, when grooves were etched with a flint, and implantation made with a blowpipe] Do I remember that silver is rather mobile in solids? Maybe silver is unwanted in your Oled as a poison, and chromium acts as a diffusion barrier. Platinum and tungsten have been used for that purpose, when gold served as a conductor but was unwanted in the underlying semiconductor. And: why shouldn't you have a thicker mesh of metal, instead of a uniform, very thin film? If the mesh is narrow, users won't see it. Current collection to the metal lines could occur by natural surface conduction, or through a separate layer. To cross 10µm distance with 1000* 10mm width, ITO conduces enough! Solar cells use a (coarse) mesh combined with a (resistive) doped layer to obtain transparency and conductivity.

-

Yes, that's it. Over two weeks, 3ns pulses separated by 500ns allowed to accumulate some 15 neutrino detections. (remember the original experiment detects the mu to tau neutrino oscillation. It's less difficult to detect the produced mu neutrinos in the flight time experiment) Their proton beam is modulated at 5ns, so if the modulator permits it, a pseudo-random sequence that keeps nearly 50% of all pulses would emit 50 pulses in 500ns, not just one. Over the same time, they would detect 750 neutrinos instead of 15, improving accuracy or waiting time. Now, if one wants to imagine what happens during the mathematical de-convolution, it's not very intuitive... People with a background for signal processing need several hours to get a usable mental image of it. But pulse compression does work in countless uses, including cell phones, and with a few particle detections as well as with a noisy signal. Imagine the experimenters want to keep two weeks integration: they get 750 detections within 40ns or 8 time bins, giving almost 100 neutrinos per bin. The mathematical pulse compression operation will produce noise in the wrong time bins, but this noise accumulates as sqrt(100)=10. (This is because, in a sequence composed of +1 and -1, a detected particle sometime adds, sometimes subtract, at the wrong bins) In the proper time bins, the signal accumulates as 100, giving 10 sigma signal-to-noise. Better than 1 event per bin as of today. This permits to interpolate the flight time to less than one time bin, and compare the distribution with the one expected from detector behaviour. Radar and sonar do this for the same reason the neutrino experiment should: they want to transmit a limited power over a longer time to increase the pulse energy, but keep time accuracy.

-

-> 98% for instance. Absorbing is never difficult, unless you approach the source's temperature. -> 4 times more efficiency means less area. -> 20% are single-crystal cells, affordable only on spacecraft. -> Because you build more units. -> Gemasolar indicates a mean power output, which is only 5MW at Fuente Álamo. Gemasolar is hence more area-efficient than Fuente Álamo.

-

The experiment has been improved using short pulses of about 3ns: http://arxiv.org/abs/1109.4897 and gives the same result, which removes many interrogations about the setup, including mines about dispersion in the current transformer and the transmission line. Next step shall add a muon detector at the source, to obtain a more direct measure of the start time (remember the chain is proton -> muon -> neutrino). ---------- Apparently, the experiment now takes short pulses with slow (500ns) repetition rate, maybe to avoid aliasing between the pulses. Signal processing techniques from radar and sonar, like frequency chirp or pseudo-random sequences or spread spectrum would still prevent confusion between the pulses but allow closely spaced pulses. For instance 50 times more pulses in the same duration would shorten the measurement campaign 50 times provided the modulator achieves it. Marc Schaefer, aka Enthalpy

-

Hello you all! A nice Solar power plant has just been inaugurated in southern Spain. It's called Gemasolar, efficient browsing keyword: http://www.torresole...asolar-plant/en http://www.nrel.gov/...fm/projectID=40 (http www) youtube.com/watch?v=GhV2LT8KVgA http://www.lemonde.f...#ens_id=1271383 (French) Why the provocative title "the Sensible Way"? - It converts Sunlight to electricity through heat. The huge light collection area is made of "cheap" mirrors, not of expensive Solar cells. - A turbine and alternator can have 40% efficiency, as opposed to <10% for affordable Solar cells. - Heat is stored in a cheap bulk material to produce electricity during night - storing electricity instead would be expensive. How expensive? The produced electricity is bought 0.10-0.20 euro above market price. Which looks good if you consider this plant produces 20MW on average: building it 100 times bigger would slash unit prices in 3 naturally. 240M euros investment for 20MW is six times more than a nuclear power plant (3G euros for 1.5GW) but this plant is the first of this model. Much of this cost is non-recurring (research) and would drop with size as well. How big? Thaaat big: 2 km2 for 20MW in a very sunny location. 1GW would need (10km)2 so you better have vast empty space. Sahara, Atacama, Namib, Neguev of course - and southern Spain does make sense, as would places in New Mexico for instance. You guessed, I like it...

-

Hello nice people! From time to time, I'd like to compute the minimum force that buckles a truss, and hand computations get quickly too complicated. So: could you recommend me a piece of software for that? What I need: - Quickly learned and installed, for Windows, free of nearly (I know that's incompatible) - Something like 30 nodes and 60 beams - Input as a text file would be just fine Thank you!

-

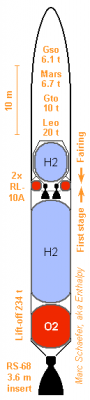

As one some Centaur stages, the fairing covers the second stage here, gaining some 700kg skin mass for the payload. The first stage extends to the upper oxygen tank, as the smaller RL-10A need no interstage that separates sidewards. (Click the image for full size) The first stage is like the Ssto, only a bit smaller. At the second stage, the tanks of 160µm steel weigh 147 and 119kg. 100kg of steel or aramide bands hold them to a truss made of AA7022 plain tubes weighing 200kg that holds the oxygen tank, the payload, the hydrogen tank and the engines. A 160kg adapter links with the first stage and the fairing. The tanks and the structure weigh 21kg per ton of propellants. This design puts a payload in geosynchroneous orbit (Gso) in two stages with little inert mass, and its payload fraction to low-Earth orbit (Leo) is outstanding. Marc Schaefer, aka Enthalpy

-

This design of an RS-68 pushed SSTO has masses and volumes similar to the other, but doesn't expose balloon tanks outside: Skin is of AA6082 with t1 = t2 = 1mm a = 45°; extrusion direction is horizontal at the hydrogen tank and vertical at the oxygen tank. Hydrogen tank heads are of 1.2mm thin AA7022. The left design holds oxygen in a Maraging balloon tank, 340µm thin, so the extrusion doesn't feel oxygen's hydrostatic pressure. The righ design holds oxygen in the aluminium skin. The top head is as for hydrogen, while the bottom is thicker AA7022 with stiffeners. Here the engine pushes the bottom directly. To resist pressure, the skin is wrapped in glued AA7075 band, nearly horizontal, the layers totalling 2.0mm at the top and 2.5mm at the bottom. Other wrapping materials would save some weight. Cold-rolled austenitic steel matches aluminium's CTE less badly than Maraging does. More than with aluminium band, pre-tension would be necessary when wrapping, to avoid worries when the extrusion is cold, and to keep the extrusion below its proof stress under pressure. Windings of fibre with polymer matrix would be even stronger but their CTE uses to be even lower. Marc Schaefer, aka Enthalpy

-

I've never found two suppliers of graphite giving similar measures for their products, so if books happen to give identical figures, then only because of copying on an other, or as a result of some computation of a material nobody has ever produced. Differences are disturbing for an element, like several % for the density. I stand by my claim that graphite doesn't burn. Mainly because I couldn't light an air suspension of graphite particles, about 50nm in size (lubricant), in a flame. I consider a material that doesn't burn under such conditions won't as a block. MSDS tell the same. The regular use of graphite as an oven liner, as well. At the provided link http://en.wikipedia.org/wiki/Windscale_fire in paragraph "Wigner energy" they tell: "uranium fuel caught fire — not the graphite moderator as is widely assumed. A 2005 inspection showed that graphite damage was localised around burning fuel elements".

-

http://en.wikipedia.org/wiki/Corundum http://en.wikipedia.org/wiki/Sapphire probably formed at high pressure. High temperature over a long time must be the key. My gut feeling: very low pressure (together with heat) won't produce a crystalline oxide, because aluminium itself is polycrystalline, and because the number of Al atoms per area unit won't match that of the oxide. You have better chances starting with the molten oxide and achieve a directed solidification, by Czochralski or Bridgman methods. http://en.wikipedia.org/wiki/Czochralski http://en.wikipedia.org/wiki/Bridgman%E2%80%93Stockbarger_technique which are common methods to produce single-crystals, including ceramics, for instance for lasers or for scintillators. For tiny amounts, you might try epitaxy at low pressure, yes, but this needs a monocrystalline seed with a compatible lattice parameter. Then Al and O2 would be brought to the growing surface as gaseous molecules, and the by-products should be gaseous as well, and here troubles begin - choice is very narrow if any, leading semiconductor technology to use dangerous chemicals like SiH4, HF, AsH3...

-

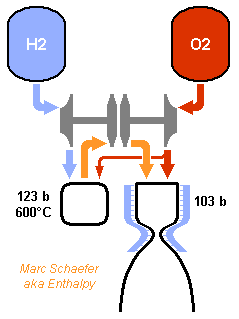

A hydrogen staged combustion cycle is simpler than a gas generator cycle for the same moderate pressure and performance: A single stage hydrogen pump after the (not represented) 20b booster pump achieves 123b in the pre-chamber, and the smaller pumping power leaves 103b in the main chamber, which gives the same performance as a gas generator cycle. The hot gas' maximum expansion speed can be shared as 691m/s and 421m/s in the single-stage turbines that power pumps with 528m/s and 141m/s tip speed. Single stages simplify turbines and pumps. Gas generator cycles exploit much faster hot gas through several stages. We can also accept some liquid leaking into the hot gas if this flows in the drawn direction, which makes seals easier. More details there http://saposjoint.ne...start=60#p34927 Marc Schaefer, aka Enthalpy

-

Torque sensors exist and work. Any development would cost you much time before you get a sensible result - and your design has known weaknesses in it. So: why shouldn't you buy a torque sensor instead? Some exist that you put at the shaft, and don't even need an electrical contact between rotating parts.

-

Charcoal and coal are hydrocarbons (with much C and little H) which allows them to burn, as opposed to graphite. Very different. Not interchangeable. Rods of coal can't replace graphite, I expect, and must be a fuel, yes. Charcoal is pyrolysed wood. Coal is extracted in mines and normally pyrolysed before use - names change in this process. Carbon is the element and is also a synonym for graphite, though some people make differences, with graphite being more heavily heat-treated. Fun: nobody knows precisely the properties of graphite, hence carbon, because it's so inconsistent. Different processes (pyrolytic, and so on) make different properties (paramagnetic), and even the same process results in different densities for instance. And it can also be amorphous, vitreous, polycrystalline and the like.

-

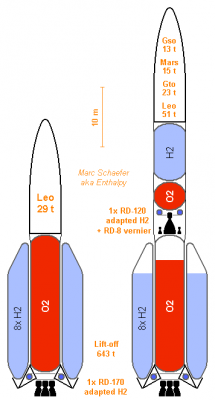

Lighter tanks make hydrogen's volume more acceptable. Their combination outperform solids to provide twice Ariane V's payload with similar mass and size, and go to geosynchronous orbit (Gso) efficiently with two stages, or to low-Earth-orbit (Leo) with one: (Click to magnify) I explained there how I hope to adapt the RD-170 to hydrogen with limited effort: http://www.sciencefo...gen-or-methane/ http://saposjoint.ne...start=40#p33663 (more detailed) to obtain from it 8.2MN and 3727m/s at sea level and 4023m/s in vacuum. The same way, Zenit's RD-120 shall burn hydrogen to produce 752kN and 4301m/s in vacuum - estimated from less detailed engine data. Alternately, the RD-180 and RD-0124, converted to hydrogen, would cut all masses by 2, which can better fit customers' needs. To reach efficiently Jupiter and beyond, add an RD-0146 stage. The RD-170 stage burns 499t of propellants - but 583t if it's alone, provided one wants bigger tanks just for that case. AA7022 extruded transversally with t1=2.7mm t2=2mm a=45° carries the oxygen and transmits the thrust; with heads and foam, this tank weighs 9.1t. Eight balloon side tanks carry hydrogen. Of 330µm Maraging steel, they weigh 6.5t together with the foam. The truss linking the engine and the tanks shall weigh 1t, but as aerodynamic lift is the main stresson hydrogen tanks, the truss won't look as I sketched. The 16.6t tanks weigh only 28kg per ton of propellants. A stacked design (D=8.4) would weigh 19.2 or 33kg per ton, marginally less than the Shutlle's external tank. The RD-170 weighs 10.8t, including 1.3t for hydrogen adaptation, and the interstage 2.0t, putting the stage dry mass at 29.4t. The RD-120 stage burns 94.9t. Its walls are of extruded AA6082 with t1 = t2 = 1mm, a = 45° and weigh 2.7t with the heads of the hydrogen section and the foam. The extrusion direction is axial below the hydrogen tank, transversal there and above. The oxygen tank is an elliptical balloon of 320µm thin Maraging steel, weighing 240kg with foam. Pressure doesn't push the extruded walls to the side. The tiny kerosene tanks supplies the pre-chamber and the vernier RD-8; together with a truss to hold the engine, they weigh 0.2t. Together, the tanks and skin (which resists up to 40% of the first stage's thrust) weigh 33kg per ton of propellants. Adapted to hydrogen, the RD-120 shall weigh 1.6t, and the untouched RD-8 0.1t. Electronics and payload adapters are granted 3.7t, putting the dry stage at 6.3t. Marc Schaefer, aka Enthalpy ================================================================== By the way, I had tried before to have a balloon tank hold the propellant's pressure, within a lighter skin that withstands only the other stresses. Before this small elliptic tank, minimal thickness at extrusions made it less interesting. But at big launchers, maybe. Like the SLS. Or if thinner extrusions can be made. Rocket technology could let extrusion improve. A machine is cheap, even tailor-made. Also, a few companies claim they extrude magnesium alloys. A mainly cylindrical balloon might be pushed by metal or fibre belts passing below and around it. Insulation foam would probably reside between the balloon and the structural wall. Less than obvious: clearance is not desired, but the balloon's diameter changes with temperature and pressure. Of course, balloon tanks can combine with a separate structural truss, where a structural wall is too heavy, as indicated at Saposjoint.net about SSTO. And aluminium extrusion makes nice struts for the truss: sounder, and easier to assemble than carbon composite. If needed, a windshield can hold on the truss, or the fairing can cover the stage(s) in addition to the payload: exists already for Centaur upper stages. Marc Schaefer, aka Enthalpy

-

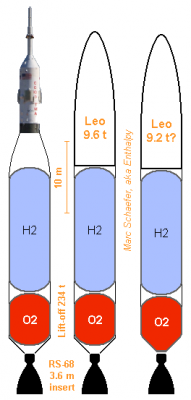

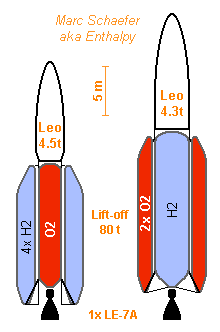

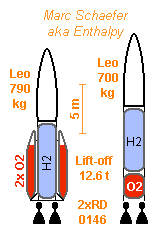

Yes, many machines exist with surprising abilities. For instance roll mills can produce zigzag sheets http://en.wikipedia....metalworking%29 But what I like extrusion to produce closed profiles, with an inner and an outer skin in one operation, with no seams that are harder to make later and less reliable. ================================================================== Here examples using the LE-7A hydrogen engine. Its D=1.815m nozzle gives 4315m/s specific impulse; a wider one may pay for its mass. With a restraint insert during lift-off, it pushes 1.02MN and brings 8763kg to Low-Earth-Orbit, minus 1832kg for the engine. The left design has a central oxygen tank of aluminium 6082, extruded in the transverse direction, with t1 = t2 = 1mm and a= 45°, which weighs 952kg with foam. Hydrogen fits in lateral balloon tanks of 180µm thin Maraging steel; four weigh 700kg with foam. A few rods weigh 200kg: this leaves 5070kg for the electronics, the adapters, and the payload of about 4.5t. Maraging sheet is hot-rolled, that's easier than cold-rolling austenitic stainless steel, and Maraging retains its strength at weld seams. A hypothetical alternative would let braze the thin sheets; stainless steel would require a coating for that, like nickel. The right design puts its hydrogen in the central tank. Here AA6005 is extruded in the transverse direction, with t1 = t2 =0.8mm and a = 45° (one extrusion company claims 0.25mm thickness is possible - this must use the weaker AA6063). This tank weighs 1500kg with foam. Oxygen fits in tanks of 300µm Maraging steel; only two pieces with foam weigh 416kg. A bit heavier, but the tanks are stronger and leave two free angles to jettison the fairing halves. 4.5t in LEO fits existing payloads. The J-2X engine may be cheaper with similar performance, but is heavier and requires a separate roll actuator; two J-2X could be more expensive than one RS-68. Marc Schaefer, aka Enthalpy ================================================================== Two RD-0146 make a tiny-cute SSTO launcher. Their D=1.25m nozzle option brings 4540m/s specific impulse in vacuum but demands a restraint insert at low altitude, pushing there 80kN each. They leave 1660kg in orbit and weigh 261kg each. The central tank relies on the ability to extrude AA6005 to t1 = t2 = 0.4mm; at least AA6063 allows 0.25mm. a = 45°, extrusion in the transversal direction. On the left design, the central hydrogen tank weighs 198kg with its heads and foam. The two balloon side tanks made of 120µm Maraging steel weigh 52kg with foam. The struts (AA7022 here, maybe graphite) add 11kg. This leaves 877kg for the electronics, adapters, and the payload of about 0.79t. The right design stacks the tanks, with t1 = t2 = 0.5mm at the oxygen tank only. This leaves only 0.7t payload. The RD-0146 and others are children of the RL10 ancestor. The RL-10A brings slightly less performance but may be cheaper. The LE-5B makes a bigger launcher and payload; Vinci and the planned US heir of the RL10 more so. The RD56 and RD56M are still little documented. At least the RL10 can throttle deeply enough. Such a tiny launcher with two cheaper engines shall provide small per-launch costs for light payloads and can be an affordable demonstrator of single-stage-to-orbit. As the RD-0146 provides roll control, it enables an even smaller launcher with a single engine. If a shell can be attached to one launcher side, 5m*11m big but light enough, and serve as a heat shield, you get a reusable launcher by adding a parachute. The expander cycle engines are easier to re-use. Marc Schaefer, aka Enthalpy

-

Only the die used to extrude the aluminium profile would be made by EDM. This die has just the transversal size of the extruded profile, not its length. As it's commonly a thick part with deep holes rather sharply concave, it must be made by EDM usually. I imagine the openings in the die could be curved to produce a curved extrusion, wrapping itself naturally on the rocket's diameter.

-

The claim in that old paper was to have produced the protein, which isn't quite the filament. More essentially, I disagree with all statements of "strongest material yet" as they always compare a single filament of their junk with a complete thread or yarn or lamination of established materials. In µm diameter, all materials are extra-strong, steel and ceramic and aramide and graphite much more so than spider silk or carbon nanotubes. Wait until someone achieves to twist a thread or yarn of their junk, you'll see how bad it really is.