-

Posts

978 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by arc

-

Acme, what you have found is a tephra that is probably from the Smith Creek Eruptive Period that occurred between 3.9 - 3.3 thousand years ago. As the link below testifies, these tephra materials have been found "as far away as 950 km (590 mi) from source." https://volcanoes.usgs.gov/volcanoes/st_helens/st_helens_geo_hist_108.html Smith Creek Eruptive Period (3.9 to 3.3 ka) "During the Smith Creek period, two periods of highly explosive activity (3.90 to 3.85 ka and 3.5 to 3.3 ka) deposited large amounts of tephra (set "Y") and pyroclastic flows. The second period was initiated with a highly explosive eruption ("Yn") that was about four times larger than the one in 1980, making it the most voluminous eruption in Mount St. Helens' history. These tephras have been identified as far away as 950 km (590 mi) from source. During late Smith Creek time, a lava dome was extruded and huge lahars swept down the Toutle River and probably reached the Columbia River." Tephra Any type and size of rock fragment that is forcibly ejected from the volcano and travels an airborne path during an eruption (including ash, bombs, and scoria). "As in earlier stages, Spirit Lake volcanism erupted mostly dacite, but significant amounts of basalt and andesite were also erupted. The Spirit Lake Stage is subdivided into six eruptive periods—the Smith Creek, Pine Creek, Castle Creek, Sugar Bowl, Kalama, Goat Rocks, and the Modern period of activity that began in 1980." http://www.geo.mtu.edu/volcanoes/hazards/primer/tephra.html "When a volcano erupts it will sometimes eject material such as rock fragments into the atmosphere. This material is known as tephra. The largest pieces of tephra (greater than 64 mm) are called blocks and bombs. Blocks and bombs are normally shot ballistically from the volcano (refer to the gas thrust zone described in the direct blast section). Because these fragments are so large they fall out near their source. Blocks and bombs as large as 8-30 tons have fallen as far away as 1 km from their source (Bryant, 1991). Small blocks and bombs have been known to travel as far away as 20-80 km (Scott, 1989)! Some of these blocks and bombs can have velocities of 75-200 m/s (Bryant, 1991). Smaller ejecta such as lapilli (2-64 mm) and ash (<2 mm) which are convected upward by the heat of the eruption will fall out farther from the volcano. Most particles greater than a millimeter in size will fall out within 30 minutes of the time they are erupted (W.I. Rose personal communication). The smallest particles which are less then .01 mm can stay in the atmosphere for two or three years after a volcanic eruption." That is a nice find I hope you kept a souvenir er I mean sample.

-

One time on a camping trip in Montana we decided to BBQ some hamburgers . . . . . . . . BAAAAAD IDEA!!!

-

Plus 1 bender. The original post probably gives the greatest clue as to the reason for the difficult disassembly. Bold mine. Aluminum is a much softer metal than the high carbon steel of the bearing raceway, and assemblies consisting of steel races pressed into a steel or aluminum housing require extremely accurate alignment during the insertion and removal processes. This process is properly done on a press designed to provide gradual and more important, aligned force, to remove and install press fit components together. Aluminum is very easily misaligned with the bearing race when it is subjected to blunt forces at angles beyond dead center to the parts axis. In other words do not use a hammer! This causes galling of the aluminum's machined surfaces which lead to the need of even more increase of forces to dislodge the raceway and many times to the permanent damage of the part through fracturing. Many smaller procedures involving aluminum require the use of an arbor press which allow for a very subtle and direct control of the ram where the operator can feel through the direct mechanical linkage the movement and forces that result. Whereby a hydraulic press could easily overload the aluminum part before the operator can respond in time to prevent damage. I have replaced many bearings over the last 40 some years. I do my own automotive repair in my own very well equipped shop which includes a 20 ton hydraulic press that I would not use to disassemble an aluminum assembly that shows signs of the corrosion or contamination mentioned without first preheating it. Any degree of the corrosion that Acme mentioned or the contamination as I suggested will only compound the difficulties in doing this process correctly with even the proper equipment let alone a hammer.

-

And in certain situations, they are a sanctuary in an ever increasing hostile world. Aircraft carriers, as already alluded to, extend the nation's boarder to wherever those task force groups are located. In other words, they become mobile islands of national territory, a technological solution to the fluid and sometimes fickle difficulties involved in a world where a land based facility in a host country could be lost within a single regime change cycle, possibly leaving an entire region less accessible. For this reason alone they are unlikely to become obsolete anytime in the foreseeable future. Even if they are found to be more vulnerable to developing weapon systems the retaliatory response should deter all but the most suicidal regime.

-

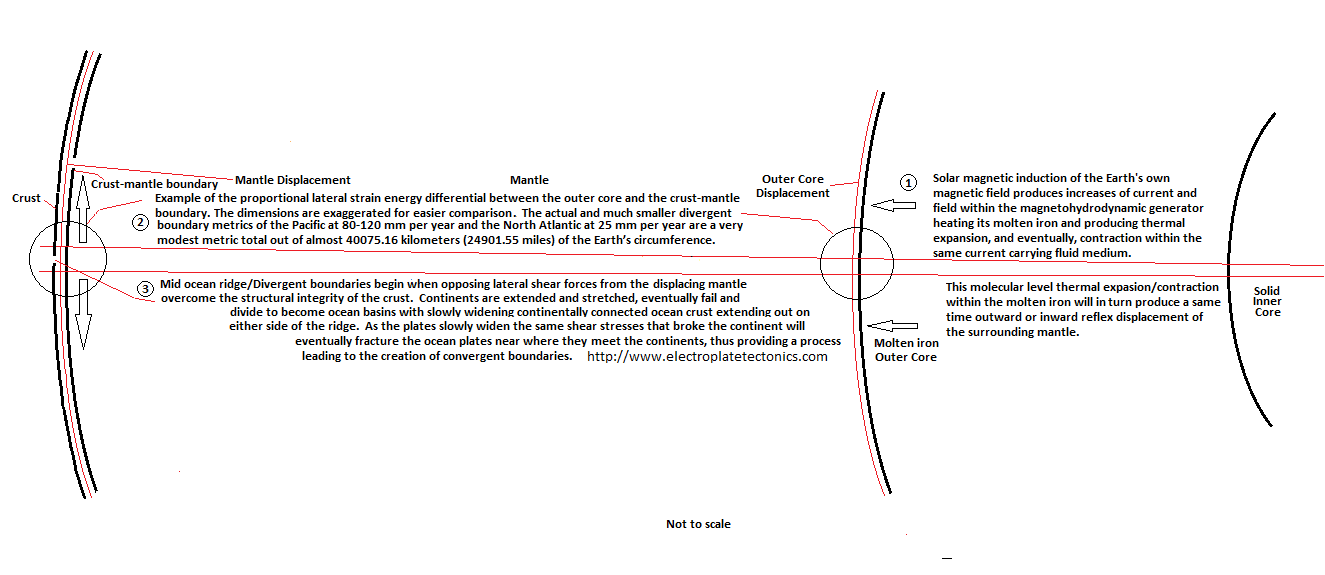

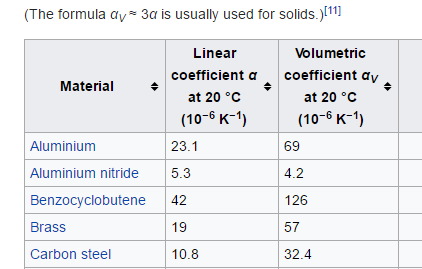

To add to Acme's good analysis; The two metals also have quite different coefficients of thermal expansion between them. And when exposed to cycles of heating and cooling, such as through friction from braking during deceleration, and forces from dynamic loading during cornering for example, these changes can allow moisture from the weather and condensation from thermal cycling to penetrate more easily between the dissimilar materials. This can accelerate the galvanic corrosion, or on their own, bring enough microscopic foreign material into the part's contact surface area to make them difficult to remove years later. The greater the difference in the coefficient the greater the space for water and foreign material to occupy. So, if your part's contact areas are still smooth and do not have the visible corrosion from electrolysis it is probably the thermal cycling alone and/or foreign material. Some manufactures actually preheat some parts before the assemblies are combined and use negative thermal expansion to hold the parts together. This, of course would require you to heat the proper part to disassemble the components. https://en.wikipedia.org/wiki/Thermal_expansion "The coefficient of thermal expansion describes how the size of an object changes with a change in temperature. Specifically, it measures the fractional change in size per degree change in temperature at a constant pressure. Several types of coefficients have been developed: volumetric, area, and linear. Which is used depends on the particular application and which dimensions are considered important. For solids, one might only be concerned with the change along a length, or over some area."

-

Brand new to the Forum/Lordy! Glad I found you! Refining Silver

arc replied to pontif's topic in Applied Chemistry

15!!! THAT'S OUTRIGHT ROBBERY!!! (so nice to have an easy way to dump the iron pyrite) -

Brand new to the Forum/Lordy! Glad I found you! Refining Silver

arc replied to pontif's topic in Applied Chemistry

Sure, but you will first need to send the material to me for closer examination . . . . . . . . -

A swing . . . . . . . . . . . and a miss.

-

By what we see almost every day it is obvious that we are moving steadily towards the future of the gradual blurring of what we now consider human and what will later be considered the increasingly technologically enhanced version of Homo sapiens. We may very well become extinct and evolve simultaneously. Who will decide this and where they draw that line would be interesting to know. But to be sure though, this time we are choosing the direction of our own evolution.

-

-

I wonder how close we could have gotten with wood burning steam driven tractors? (supplemented by large solar thermal mirrors of course)

-

Lets discuss the questions not allowed to ask on this forum

arc replied to pittsburghjoe's topic in Speculations

Let's not. -

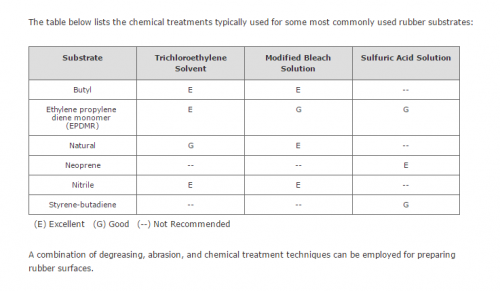

This site may have some useful information. http://www.masterbond.com/resources/surface-preparation-for-rubbers The three most common techniques used for surface treating rubber substrates are: Trichloroethylene Solvent: Degrease the rubber substrate as mentioned above using trichloroethylene solvent. Modified Bleach Solution: Prepare the modified bleach solution by pouring cold DI water (1 liter) into a clean container made of plastics, glass or similar inert ware. While stirring the water, add concentrated hydrochloric acid (5 ml) in a slow steady stream. Then add household bleach (30 ml), stirring it thoroughly into the diluted acid. Immerse the rubber substrate in modified bleach solution for 1-3 minutes at room temperature. Following that, rinse it in cold DI water, followed by a rinse in hot DI water. Finally dry the substrate in hot air. Sulfuric Acid Solution: Immerse the rubber substrate in concentrated sulfuric acid for 2-10 minutes. Following that, rinse it in cold DI water, followed by a rinse in hot DI water. Finally dry the substrate in hot air.

-

Just a reminder, not meaning to distract from the OP, but, whether you use wind, water, coal, gas or any other examples you are actually using solar energy. It's just each one has a specific time delay specific to its derivative process to and from the solar source. Fossil fuel being probably the oldest (photo synthesis) (or would it be nuclear from some primordial star?), and photo voltaic being the most instantaneous source with the others assuming their respective positions along their own mechanistic timeline.

-

. . . . and Plate Tectonics. Ophiolite, how could you leave this one out?

-

A fun question: Logic in a geometrical concept.

arc replied to cercig's topic in Analysis and Calculus

Nature always moves to the lowest energy state. If a volume of water is placed in a zero gravity environment it forms a perfect sphere which is the lowest energy state it can attain. You are observing a two dimensional abstract example of this principle, and can observe its graduated numerical representations by manipulating the boundary's shape. As the volume of the shape increases the surface ratio of angled corners will decrease in proportion. Think of a star shape utilizing as many corners and sides as possible. Pressure containment and structural load bearing designs naturally take advantage of this principal so we all rather sense this in an almost subconscious expectation of the world around us. Edited for clarity. -

You are likely seeing the result of the installation of an EFIS system on the exterior of a building. https://en.wikipedia.org/wiki/Exterior_insulation_finishing_system This video below is not an EFIS installation but it does show how much of the polystyrene foam is lost with just a small amount of processing. Normally the flat polystyrene panels are screwed to the building's exterior and then covered with a mesh on to which a thin layer of stucco is applied. Normally the panels need to be cut to fit around window and door openings, and when smaller pieces are needed at corners and other transitions. The mess is made when these panels are cut to size, usually with just a hand held carpenters saw. When they want the buildings to have architectural accents like enormous bull-nose cornices they will stack and layer large dimensional polystyrene foam pieces together and then sand them to shape with large rasp sanding boards. I have seen at one construction site what looked like a snow storm as a dozen workers sanded off a 1/3 to a 1/2 of the material to gain the desired shape. The stuff was blowing down the street and piling up as drifts against curbs and buildings. These were mostly the tiny round foam components that make up the bulk material. The debris in the video is even finer and will stay airborne for great distances. Much of this mess can be eliminated if architects avoid custom shapes and use factory available pieces.

-

The turbine in that vacuum is rated at 338 KPH, I don't think an exploding egg would stand a chance of getting ahead of that if it went off as it was going in the nozzle. I would like to see some videos of the results though. Where are the Myth Busters when you need them.

-

I believe the most enjoyable way to be introduced to this subject would be David Attenborough's Rise of Animals: Triumph of the Vertebrates. It's a two part documentary, 60 minutes each. I can watch these over and over. Great CGI effects and David Attenborough's unmatched presentation abilities. https://en.wikipedia.org/wiki/David_Attenborough%27s_Rise_of_Animals:_Triumph_of_the_Vertebrates

-

The military would keep their system no doubt.

-

You can buy high efficiency bags for that vacuum, so all you would need to clean is the hose. But you could also just replace the hose, they are not very expensive. And you can find the eggs you cannot see by mounting a mirror (old car mirror) on the end of the pipe to see downward. You can add a 30 or 45 degree coupler to the end to aim downward, just make sure the pipe size is large enough to accommodate an angled coupler that an egg will fit through. Or just go for breaking and sucking up the remains.

-

If all I wanted to do is break the eggs I would get one of these air powered pellet rifles. It has a flashlight and laser to pinpoint the target. http://www.sportsmansguide.com/product/index/gamo-big-cat-varmint-air-rifle-with-scope-laser-light-combo?a=444174 $144.90 0.177 cal · 1000 fps But I myself would just suck them up with a powerful shop-vac. This is the one I have and I really like it. You will probably need one with around 5 HP for this application. https://www.amazon.com/gp/product/B0023EY052/ref=as_li_qf_sp_asin_il_tl?ie=UTF8&tag=toolconsult-20&camp=1789&creative=9325&linkCode=as2&creativeASIN=B0023EY052&linkId=3faf6b9042d7e535f08b577e35480a80 Get some schedule 20 white PVC plastic pipe with an inside measurement as close to the egg's diameter as possible. And connect them together with some PVC couplers; Buy as many 3 meter long pieces of pipe as required and cut them as needed. They are quite inexpensive. You can use PVC glue to connect the pipes together but I would recommend just duct taping them, or better yet, just use some very short screws that won't extend inside of the pipe's interior to stop or break the eggs as they come through. You really want to be able to adjust the pipe length quickly and easily so you can move to the different locations without to much trouble and still be as close to the access opening as possible to see what's going on. With the vacuum turned off you can slide the pipe end up to the egg and the hit the switch to suck-up the egg, then switch it off before moving to the next target. You can mount a flashlight to the pipe or just get a powerful spot light and/or someone to point it at the target. It's hard to see into a dark area when you are outside in the bright daylight, it is much easier to do this at dusk or nighttime. BTW I have been removing wasp nests around the homestead with this setup for years. I use the 12.5 mm pipe size and just put the pipe end near where they come and go out of the nest. After a while there are not any of them left outside the nest and all the ones that have tried to get out are gone also. I then just shoot a little pesticide it the nest opening and the job is done. Empty the vacuum a few days after, they are always dead or near to it. 8 plus hours in a swirling vacuum vortex takes all the fight out of them.

-

I think this is the best option for the money; This neat little scooper should take the snow out to the street or one side of the driveway with a lot less effort than a shovel. Apparently, the fine citizens of Upper Michigan have classified this as a state secret.

-

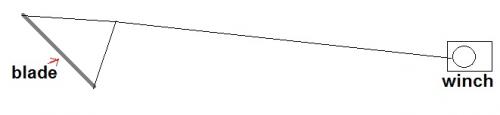

The problem with this design is it will steer to the side of its leading edge. It is basically a rudder moving in the direction of least resistance. Old horse drawn designs were commonly home built and triangular to eliminate any uneven side loading. But they would/could only do that for the first run-through, so they had to be made wide enough to clear the desired width within one run. Deeper snow would of course be handled by repeatedly covering the same path as many times as necessary. Another solution is to have a side board along the same side as that of the plow's leading edge to counter the side force that the singe blade design produces. This is a nice feature because its length can be adjusted to compensate for the snow's density and the blade's attack angle and the depth of the blade's cut (bite). A draw beam centered and rigidly attached to the blade would give the best control and eliminate the "shimmy", or side to side yaw that would occur with that bridle arrangement. The draw beams length can be quite long, to not only add the mentioned stabilization but to also create a down force on the blade edge. This can be further controlled by a means of an height adjustable wheel or ski towards the front of the draw beam to optimize the blade's pitch. The draw beam also provides a ideal support structure for the side board that needs to run parallel to the beam by its attachment means, some vertical adjustment would be desirable here also. At this point it would take two operators; one to operate the winch and one to handle the snow plow. Moving the winch to the draw beam would eliminate one of these people and switching to a gas engine would eliminate the power cord. At this point a machine such as the one suggested by Mordred would be the best choice. This is because the snow plow is a cumbersome solution at best, that really only work well when on wheeled or tracked equipment with adequate traction. And just for fun; http://www.snowplowtalk.com/#sthash.dAVCq3Md.dpbs A company based in North Carolina by the name of SuperDroid Robots has developed a robot that would plow snow for you while you sit back and relax. The robot will cost you about $8,500 and will prove most useful if the snow level lies between 2-6 inches. The robot is a six wheeler and comes with a plough blade which is 52” in length and works pneumatically. The robot can be controlled via tablet or your desktop PC. It weighs about 181.82 pounds and is capable of running for two hours on two car batteries. However, there is room for more batteries and hence, more work time. The RoboPlow will actually clear your driveway of snow while you have breakfast. So watch out snow plow manufacturers, because the winter is no match for RoboPlow.

-

If a chicken lays an egg in the forest and no one is there to hear it . . . . . . .